Core Design Factors Influencing Stretcher Costs

Basic Transport vs. Specialized Medical Stretchers

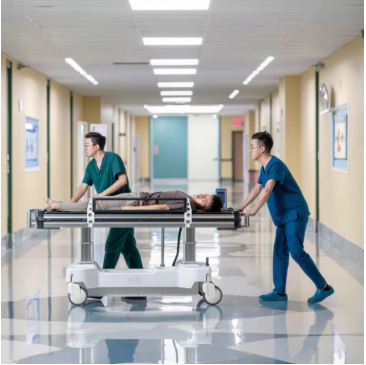

Basic transport stretchers and specialized medical stretchers serve distinct purposes, with their design and functionality tailored to diverse healthcare needs. Basic transport stretchers are primarily used for moving patients within healthcare facilities and feature straightforward designs, often lacking advanced medical components. In contrast, specialized medical stretchers are designed for emergencies, surgeries, and intensive care, often incorporating adjustable height, foldability, and advanced materials. These features not only enhance patient comfort but also contribute to higher manufacturing costs. According to reports from healthcare equipment suppliers, specialized stretchers are becoming increasingly popular, with costs reflecting market trends and advanced features. For instance, stretchers equipped with imaging capabilities and powered functions might cost between $8,000 and $9,000, as observed by market experts like Kenneth Ross from ECRI.

Customization for Specific Procedures

Customizing stretchers for specific medical procedures adds significant value, though it also increases costs. Hospitals frequently pursue customization to suit particular patient needs or specialized medical functions. Common adaptations include integrated monitoring systems and safety features that enhance patient care but come at a premium price. Such stretchers may cost significantly more than standard options due to the inclusion of these specialized components. Statistical data suggests that customized stretchers can range from $8,000 to $15,000, depending on the complexity and the included features. As healthcare providers weigh these options, they often consider the added costs against the potentially enhanced quality of patient care facilitated by these bespoke enhancements, a sentiment echoed throughout industry discussions and by medical equipment specialists.

Technological Enhancements and Price Impact

Powered Mobility Systems

Powered mobility systems have revolutionized stretcher use by enhancing functionality and efficiency in medical environments. With innovations such as electric height adjustments and remote controls, powered stretchers have become increasingly popular. These features significantly improve usability, especially in fast-paced settings like emergency rooms. For instance, powered stretchers like the ones with a drive feature and fifth-wheel steering have become industry standards, with costs ranging from $8,000 to $9,000. However, while these technological advancements enhance patient transport efficiency and safety, they come with additional costs. Kenneth Ross, ECRI's senior program manager, noted that although motorized drives add convenience, they also lead to higher purchase and maintenance expenses (Source: modernhealthcare.com). Nevertheless, their practicality in handling heavier patients can outweigh these costs, influencing purchasing decisions in many healthcare facilities.

Integrated Medical Equipment

The integration of medical equipment into stretchers has become a key factor influencing overall costs. Features like built-in oxygen tanks and monitoring devices are increasingly in demand as healthcare providers seek ways to optimize patient care. The trend toward multi-functional stretchers that incorporate these advanced technologies is growing, reflecting an increased demand for comprehensive care solutions. Market research reveals that this demand directly impacts stretcher pricing. With more healthcare facilities opting for such enhancements, the cost implications are evident, as the integration of medical technology necessitates more sophisticated manufacturing processes and materials. Consequently, while these integrated systems raise the initial purchase price, they offer invaluable benefits in terms of efficiency and patient monitoring, often justifying the additional cost in a busy medical setting.

Material Choices and Long-Term Durability

Stainless Steel vs. Aluminum Construction

The choice between stainless steel and aluminum significantly impacts the durability, weight, and maintenance of hospital stretchers. Stainless steel offers superior strength and a longer lifespan, making it a preferred choice for facilities prioritizing longevity. However, these benefits come with a higher price tag, primarily due to the material's robustness and resistance to corrosion. Aluminum, on the other hand, is lighter and generally more affordable. It offers easier maneuverability but may require more frequent maintenance and has a shorter lifespan. Industry standards often lean towards stainless steel for environments with high usage and rigorous demands, as reflected in several healthcare material selection studies.

Weight Capacity and Lifespan Considerations

Weight capacity is a critical factor influencing the design and cost of hospital stretchers. High-capacity stretchers, which accommodate patients weighing up to 750 lbs, require more durable materials, inevitably increasing costs. Investing in higher-quality materials like reinforced aluminum or specialized composites not only supports greater weight but also enhances the lifespan of the equipment. According to industry data, stretchers with robust construction typically have a lifespan of 10-15 years, making them a cost-effective choice over time, as fewer replacements are necessary. This longevity underpins the economic rationale behind selecting materials that initially might seem more expensive, emphasizing the balance between upfront costs and long-term value.

Regulatory Compliance & Bulk Purchase Strategies

Certification and Testing Expenses

The significance of certification and rigorous testing for hospital stretchers cannot be overstated. These measures ensure patient safety, affirming that the stretchers meet stringent regulatory standards like those from the FDA and ISO. Compliance with these regulations often incurs additional manufacturing costs, which can significantly impact the overall pricing of hospital stretchers. For example, the cost of securing FDA approval can be substantial, affecting both production timelines and budgets. Studies show that regulatory compliance can increase the cost of medical devices by 10-20%, reflecting substantial financial implications for manufacturers. As healthcare providers prioritize patient safety, they must weigh these costs when selecting stretchers that adhere to global safety standards.

Volume Discounts and Supplier Agreements

Bulk purchasing strategies can offer hospitals considerable cost reductions in stretcher acquisition. Engaging in long-term supplier agreements can enhance these benefits, fostering mutually advantageous partnerships that are often accompanied by volume discounts. Common practices include negotiating lower per-unit prices and securing extended warranties, which can provide additional value. Successful case studies highlight hospitals that have effectively implemented bulk purchasing strategies, such as a Massachusetts-based health system that reported a savings of 15% on stretchers by consolidating purchases through a group purchasing organization. These strategies not only reduce costs but also streamline procurement processes and ensure consistent supply chains. By leveraging the power of collective negotiations, hospitals can significantly enhance their budget efficiency when acquiring essential equipment like stretchers.

FAQ Section

Q1: What is the difference between basic transport stretchers and specialized medical stretchers?

A1: Basic transport stretchers are used for moving patients within healthcare facilities and are simpler in design. Specialized medical stretchers are designed for emergencies and intensive care, featuring advanced materials and adjustable components for enhanced patient comfort.

Q2: How do customization options affect stretcher costs?

A2: Customization options such as integrated monitoring systems increase the value and functionality of stretchers but also raise their costs.

Q3: What technological enhancements influence stretcher costs?

A3: Technological advancements like powered mobility systems and integrated medical equipment improve efficiency but increase costs due to sophisticated manufacturing processes.

Q4: Which material is better for stretchers, stainless steel or aluminum?

A4: Stainless steel offers strength and a longer lifespan but at a higher cost; aluminum is lighter and more affordable but requires more maintenance.

Q5: How does regulatory compliance impact stretcher pricing?

A5: Regulatory compliance, involving FDA and ISO certifications, adds significant costs to production, reflecting in stretcher prices.

Q6: Can bulk purchasing strategies lower stretcher costs?

A6: Yes, bulk purchasing strategies and supplier agreements can reduce costs through volume discounts and streamlined procurement processes.